You’ve been loving our ever so popular Abalone and Mother of Pearl Shell sheets recently over on instagram, but even more so we’ve loved seeing you using them in your projects. We’ve been tagged in some stunning projects and it’s lovely to see you get creative with the different materials and colours that you’re using. We know a lot of you are new to using the sheets, or would just like a more in-depth look into selecting the right ones and using them correctly, so we’ve created this complete guide for you.

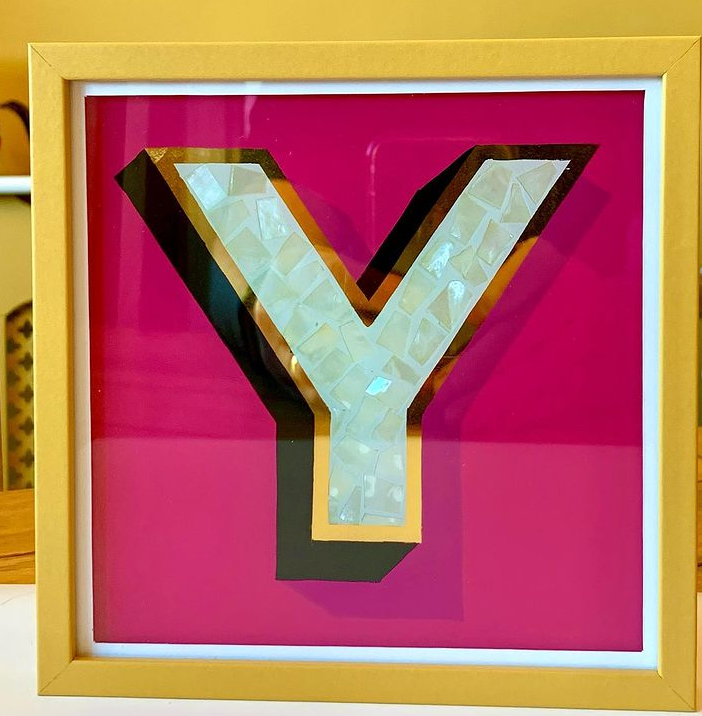

Reverse glass artwork by @gold_on_glass

Grab your tools and read ahead to learn everything you need to know about working with our Abalone and Mother of Pearl Shell sheet

So, What are Abalone and Mother of Pearl Shell sheets?

They’re traditional materials that have been used by craftsmen for centuries, in a variety of different decorative projects. Ours are slightly thinner than the ones that are used for traditional furniture inlay, making them perfect for reverse signwriters that want to add accents to their glass artworks. Since the material is very thin, they have a high level of transparency allowing light to pass through, adding to its decorative effect when used on glass. They’re also ideal for applying to the front of a variety of surface finishes and decorative projects, allowing you to create the effect of abalone inlays at a cost-effective price, this approach works well for projects on Yachts, in Hotels or for high-end interior projects. Most of the shell’s life is spent in water, so although they would look beautiful outside, having them exposed to the elements outside on exterior projects might not be the best place for them. Each sheet is made up of smaller strips of the natural shell, layered on top of each other, with every layer finely hand-sawn from an ethically sourced abalone shell and Mother of Pearl. The strips are then colour matched before being bound together by an epoxy resin, giving each sheet a pleasant and consistent colouring. Some variation might appear from sheet to sheet, making each one unique! So it’s important to remember before ordering that the look and colours of the sheet can change depending on the lighting and angle you’re viewing it at, it’s a natural material so some colour variations can appear. We always recommend creating test pieces when using the sheets before going full-scale on your project. Some sheets are translucent, and the appearance of colour will vary based on the coloured surface layered underneath the sheet. For example, placing gold under a sheet will create a different effect then if you layered a sheet with blue.

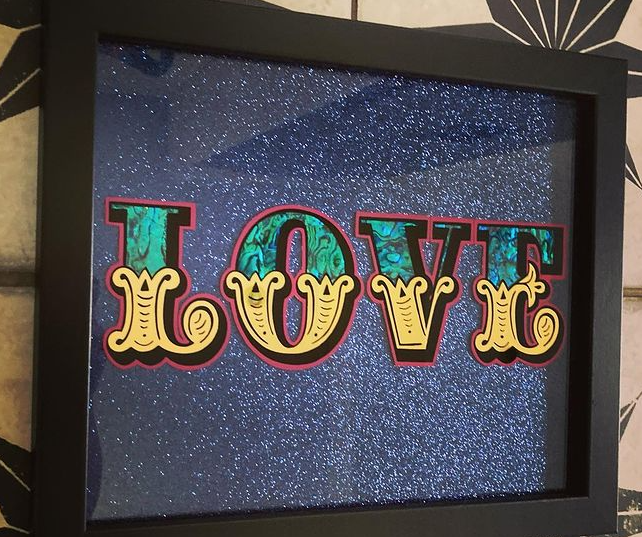

Some sheets are backed with colour, which enhances certain patterns, dark or black backings will show the full depth of colour and pattern in all its beauty. Reverse glass lettering by @signsandart

What types of sheets are available?

We stock both our Abalone and Mother of Pearl as single sheets, measuring 24cm x 14cm. Other larger sizes are available to order, we currently offer 200 x 200m, 300 x 300mm. However, if you’re looking for larger sheets we may be able to supply them in some designs, please contact our office to see what we can do for you, our lead time is around 6 to 8 weeks. There are three different ranges across the sheets, Standard, Premium and Flexible. Sample sheets of our Standard and Premium ranges are available on our website with a sample sheet coming soon for the Flexible sheets. Before you order a sample, let’s take a look at the differences between the three.

Standard Range

Our standard range varies in thickness, from 0.11mm to 0.5mm, the thickness of the sheet depends on whether it has a painted back and the style of shell.

Premium Range

The Premium range is slightly thicker, these sheets vary from 0.30mm to 0.55mm, like the standard range the thickness depends on the style and backing. It’s not just thickness that sets these sheets apart, we handpicked only the most flawless of these shells for the best possible finish. The strips are colour matched before being bound together by epoxy giving each sheet a beautiful consistent colouring, through variation may be visible from sheet to sheet. The sheets are then coated with a glossy urethane varnish, giving them a silky smooth finish. The varnish also deepens the colours as well as a measure of protection for the shell.

Flexible Range

These sheets can be cut with scissors, making them ideal for a wide range of projects, from furniture upcycling to art and surface decoration. Each sheet has been ultra-thinly cut to, giving them flexibility the thicker sheets don’t have, they’ll conform to curves. The sheets also come supplied with a super-strong self-adhesive backing that will stick to most surfaces.

How do I use them?

If your working with our flexible sheets, they can be cut with scissors and are much easier to work with, but aren’t suitable for all applications, this range also comes with a 3M adhesive backing so you can peel off the paper and stick them directly. The difficult, but worth it part when working with the standard and premium range sheets is in the cutting. They can be brittle and prone to cracking or breaking if you overstress them. There are three methods of cutting them to shape – 1 – You can use a laser cutting machine, this is the most convenient way of cutting them to your desired size and shape. 2 – Use a scalpel or hobby knife to score the sheet deeply, taking care not to use too much force that could break or crack the sheet. You can then complete the cut on a second pass for a nice, clean-cut finish. 3 – The second option is to soak the sheet in some warm water for 20 to 30 minutes – the heat helps soften the material, making it a little less rigid and brittle. It can then be cut more easily using sharp scissors without it cracking or splitting, it’s even possible to get slight curves in your cutting. When it cools down it should return to normal. Once you’ve cut the sheets, the standard and premium ranges of abalone and mother of pearl can be stuck to any surface using glues. Superglue (cyanoacrylate glue) is highly recommended, but we’ve seen people use clear varnishes and similar products as a bonding agent. The sheets are quite light so you don’t need a high-strength adhesive to keep them in place if you’re working on a decorative project.

Reverse glass sign by @signhiveuk

If your working with our opaque shells on a surface that isn’t glass, it’s possible to use two pack adhesives when applying to wood-based surfaces such as PVA or similar products, but try to avoid any adhesives that need a lot of evaporation to harden as the shell doesn’t provide a lot of air.

What about aftercare?

Any coloured shell will fade over time, however, coating the shells in UV resistant varnish will allow it to stick to glass surfaces while also sealing and protecting it from light. The varnish we recommend for this is One-Shot Speed Dry UV Resistant Varnish, but other proprietary UV varnishes will work ok. Remember to always test a small area of the shell first to make sure any added colour is not affected by the varnish! If you’re taking care of shell elements, such as small pieces of shell set inside a letter or logo which are attached to the back of glass surfaces, we recommend cleaning extremely carefully using damp chamois leather, to help prevent any unwanted snagging and raised corners or edges. If the shell has been used in a project for surface decoration, then like any natural material, its best to use non-abrasive and natural cleaning products. Depending on the application, for example, for furniture with a sealed rebated section, nearly any non-abrasive cleaner can be used when paired with a soft cloth. If you found this blog post useful keep an eye out for more blog posts coming soon. And if you use this guide when working on one of your projects tag us in your posts, we love to see photos and videos of your projects! The links to our products provided in this blog post are only a guideline for the requirements of a project involving our Abalone and Mother Of Pearl Shell Sheets. Each project may have different requirements and therefore will call for different products to be used.